I really don't need humidity readings, but the sensor I had on hand included it so I might as well use it. I decided to use a Raspberry Pi Zero and an off-the-shelf temperature/humidity sensor for the monitor.

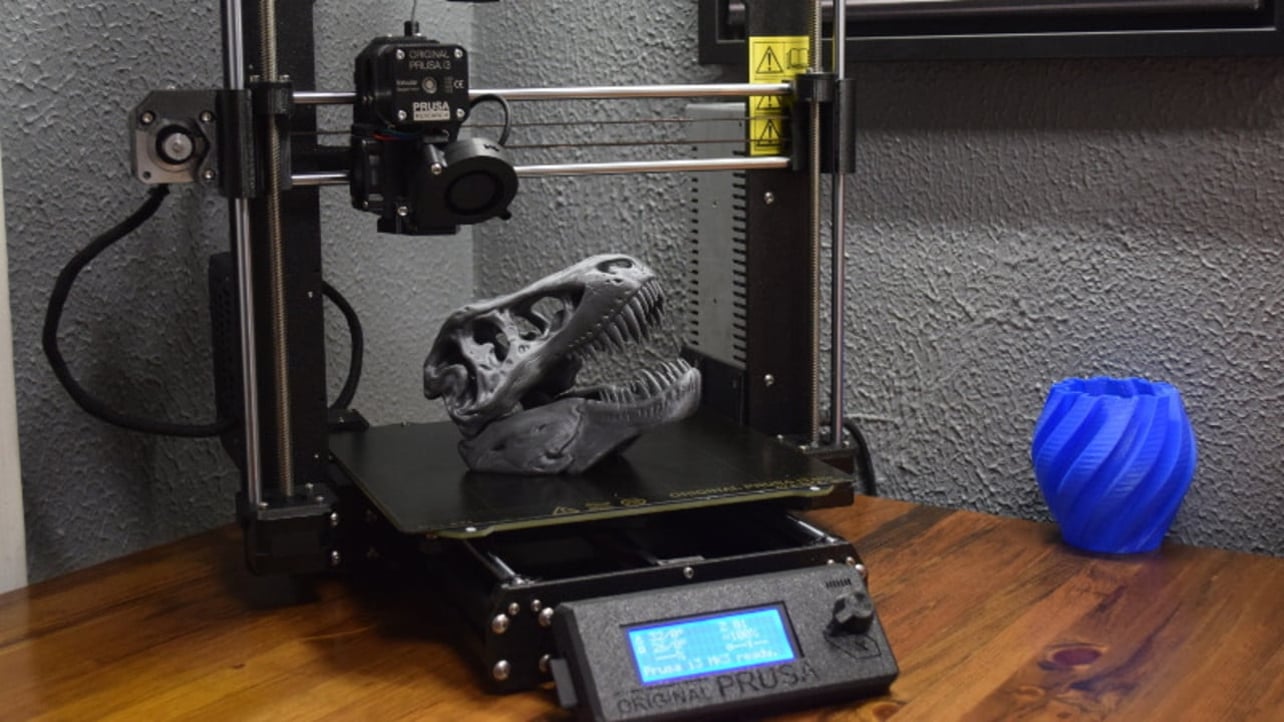

PRUSA I3 MK3S 3D CLOCK FREE

This next section has to do with the temperature monitor and fan controller, and if you're not interested in this part, you can feel free to skip to the in-place installation below. Total clock time from inventory to mostly-complete enclosure was about two hours, including adequate breaks.Ī very nice plastic spool holder is included (some assembly reqired) and can be placed on top and the filament passed through the wide slot (look closely) to the printer. I really don't think it's important to show the step-by-step parts of the assembly, as it's so easy. I decided to first assemble the enclosure with all bolts finger tight, thus allowing the final tightening when the enclosure is in the final position and dimensionally stable. There are far more nuts and bolts than necessary included. There are corner brackets, side brackets, door hardware, and various items such as plastic grommets for the cables and PTFE tubes. I followed this admonition carefully, and quite a bit of the clock time of the actual assembly was taken up by the removal of the protective sheets from the pieces. The one thing TFM emphasized is the importance of removing the protective sheets from the acrylic panels by placing the panel on a flat surface and pulling the sheet off slowly and diagonally to avoid damage from mechanical stress. I did, however, follow along, step by step, with the manual. I must say that with this kit, TFM is really not necessary, as the assembly is quite intuitive and it only goes together one way. When assembling a kit, I always RTFM, front to back, sometimes more than once. Yes, I know that the rug could use a good cleaning, but this room is not on the 'inspection tour' of our home. I also use it to assemble the larger 3d prints I do. The spare bedroom floor was used as the assembly area. The pieces are professionally cut and drilled. Nope, no Haribo bears included in this one. The first step was to inspect and inventory the contents of the box, which was complete and undamaged.

The shipment was prompt, only a few days via UPS Ground, at a reasonable cost. I intend to kind of use it for both, mainly for print quality, but also so I can keep the temperature in the home office in the low 70s (F) as opposed to the high 70s that I have been using since I got the 3d printer.Īnother extra-cost option which I declined was the knurled metal knob for the door. The 3d Upfitters site explained that some use the enclosure for better prints and some use it for better air quality. I want to control the temperature of the enclosure within one degree or so if possible. Much of this report contains some details of my own temperature monitor and fan controller, which I decided upon in lieu of the optional temperature monitor only option, at extra cost, which is available. I specifically like this version because it has a portal to supply room air directly to the I3 power supply, thus eliminating the need to perform major surgery and move the power supply to the outside of the enclosure. I found that when all items were considered, particularly the cost of the time involved, the kit is of the same order of magnitude, price-wise, as a homebrew enclosure. The specific version I ordered is on line here:

I settled on the 3d Upfitters model after reading online reviews and posting one query here. I considered two types, one a homebrew enclosure, made of stock panels and hardware, and a 'kit' version complete with most everything. I wanted to improve upon that and eliminate the extra time and extra filament used when using the draft shield, so I considered an enclosure.

PRUSA I3 MK3S 3D CLOCK PC

I do a fair amount of ABS printing, and lately even some PC Blend, and I've found that an overall improvement in print quality results from using the 'draft shield' option available in some slicers. This is a review and report on the 3d Upfitters Prusa Acrylic Enclosure Kit, specifically the MMU2S model. 3d Upfitters MK3S/MMU2S acrylic enclosure.

0 kommentar(er)

0 kommentar(er)